A LAND TO DISCOVER

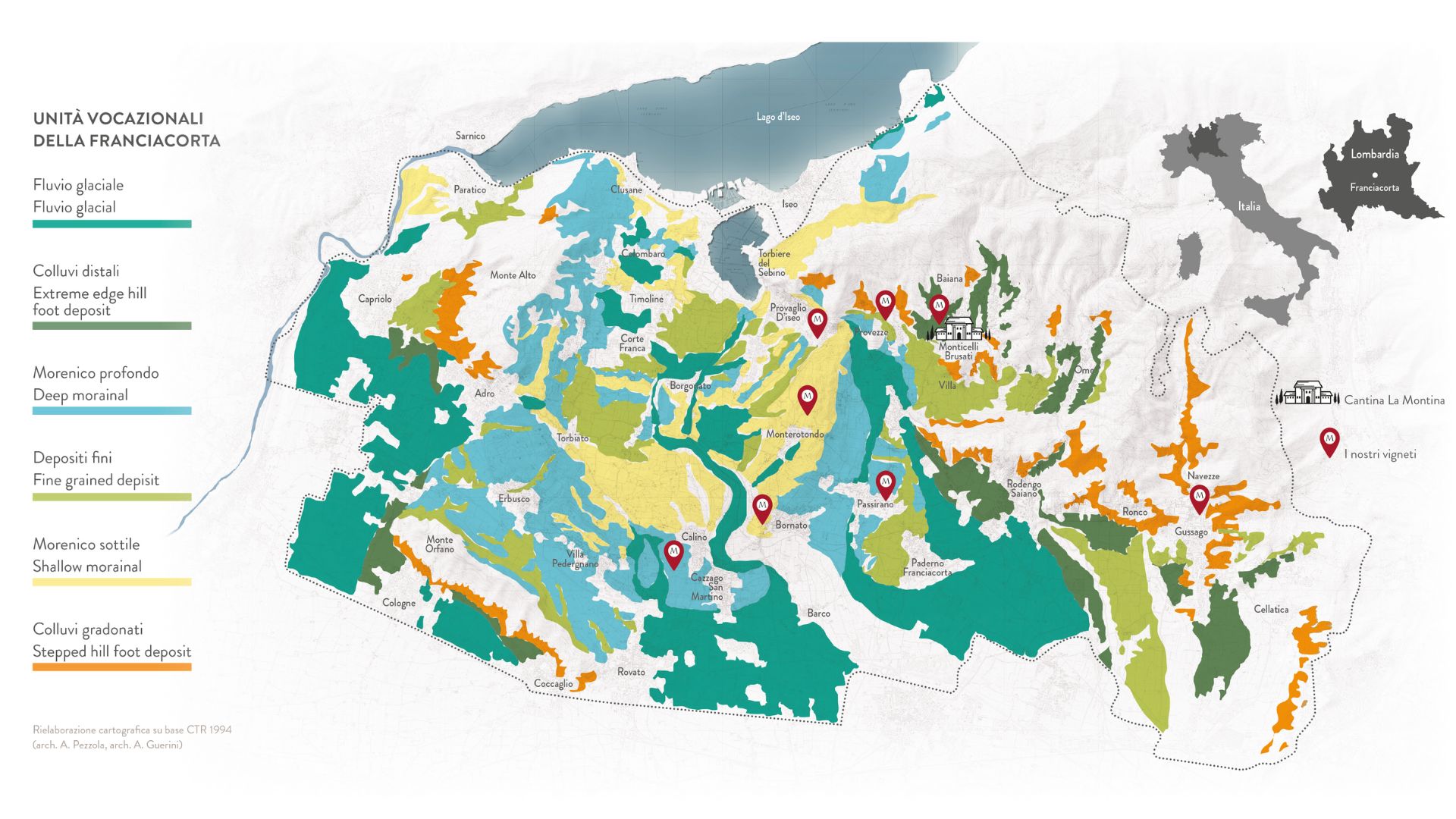

Franciacorta is located in the heart of Lombardy, just a few kilometers away from Milan, overlooking the shores of Lake Iseo, in an area of about 200 square kilometers that includes 19 municipalities in the Province of Brescia.

Its gentle hills, bordered to the west by the Oglio River and to the northeast by the last foothills of the Rhaetian Alps, owe their ancient origins to the glaciers that, retreating in the Second and Third geological eras, created the amphitheater within which Franciacorta came to life.

From a climatic standpoint, being located at the northernmost extreme of the Po Valley, nestled in the pre-Alpine system, and situated south of Lake Iseo, Franciacorta, while experiencing a continental climate, benefits greatly from the proximity of the lake, which has a significant moderating effect on temperatures. The vegetation of Franciacorta is typically Mediterranean, as evidenced by the widespread presence of olive trees that allow for the production of excellent quality olive oil.

Due to the lack of exhaustive historical documentation, the origin of the name “FRANCIACORTA” remains difficult to interpret and define today. The most accredited hypothesis is that the origin of the term Franciacorta derives from “curtes francae,” free courts, areas exempted from the payment of taxes.

The term refers to those small communities of Benedictine monks settled in the Early Middle Ages in hilly areas near Lake Iseo that were exempt from paying duties to Lords and the bishop for the transport and trade of their goods to other states or possessions, as the monks were dedicated to the reclamation of the assigned territories and instructed the peasants in the cultivation of the fields.

The study of zoning

The interaction between vines and the environment

In the second half of the 1990s, a meticulous zoning study was conducted in the Franciacorta wine-growing territory by the University of Milan, under the guidance of Attilio Scienza, aimed at defining, with a scientific approach, the oenological vocation of the entire basin, studying and evaluating the effect of the set of geopedological, morphological, and climatic characteristics of the territory on the productive and qualitative performance of the vineyard.

It is thus possible to accurately classify the territory, providing very precise indications for each homogeneous unit on the type of soil, the most suitable grape variety to cultivate, and how this grape variety will behave in that area and the resulting wine.

Six vocational units have been identified: fluvial glacial, extreme edge hill foot deposit, deep morainal, fine grained deposit, shallow morainal and stepped hill foot deposit.

Six different terroirs, which testify to the heterogeneity and richness of Franciacorta viticulture, with different soils in terms of texture, fertility, and drainage capacity, which in turn determine different vegetative-productive behaviors, different grape ripening dynamics, and finally sensory characteristics in the base wines.

The pedological study and the drafting of vocational units for Franciacorta (and Curtefranca) guarantee the possibility of a more conscientious production and safer expectations about the final product, as each one has distinctive characteristics and each gives a certain type of peculiarity to the grapes.

Aware of how different subsoil formations make a difference, Montina has decided to cultivate vineyards in areas of Franciacorta belonging to different vocational units.

72 hectares in total, between leased and owned, located in 7 of the 19 Franciacorta municipalities: Monticelli Brusati, Provaglio d’Iseo, Monterotondo, Passirano, Bornato, Gussago, and Cazzago San Martino.

For the production of Franciacorta, Montina uses only noble grape varieties of Chardonnay (80%) and Pinot Noir (20%).

THE METHOD

It’s the Franciacorta method that still guarantees the quality of each individual bottle today.

Strict and meticulous rules to obtain wines of absolute quality: exclusive use of noble grapes, hand harvesting, natural refermentation in the bottle, followed by slow maturation and refinement on the lees, not less than 18 months for the base wines, 30 for the Millesimati, and as much as 60 months for the Reserves.

THE PHASES of the Franciacorta Method

Montina Franciacorta wines are produced following the strict regulations of the Consortium of Franciacorta Wines, of which it is a part, the most stringent in the world concerning the production of Classic Method wines.

The Franciacorta method, well codified in the DOCG regulations, generally referred to by others as “classic,” imposes procedures and standards to be strictly adhered to in order to elevate its quality.

Starting from the territories where the vineyards must be located (municipalities of Paratico, Capriolo, Adro, Erbusco, Corte Franca, Iseo, Ome, Monticelli Brusati, Rodengo Saiano, Paderno Franciacorta, Passirano, Provaglio d’Iseo, Cellatica, and Gussago, as well as part of the territory of the municipalities of Cologne, Coccaglio, Rovato, and Cazzago S. Martino […] and part of the territory of the municipality of Brescia) and the grapes used:

- Franciacorta must have, as ampelographic composition, Chardonnay and/or Pinot Noir. Pinot Blanc grapes can also contribute to production, up to a maximum of 50%, and Erbamat grapes, up to a maximum of 10%.

- Franciacorta Rosé must be obtained from Chardonnay grapes up to a maximum of 65% and Pinot Noir grapes for at least 35%. Pinot Blanc grapes can be added up to a maximum of 50% and Erbamat grapes up to a maximum of 10%.

- For Satèn, Chardonnay grapes must be a minimum of 50%. Pinot Blanc grapes can contribute to production, up to a maximum of 50%.

More information about the regulations and wine types is available on the official website of the Franciacorta Consortium.

HARVEST

Grape harvesting must be carried out exclusively by hand, and the transportation of the grapes to the pressing center must be done in a way that does not compromise the integrity of the cluster.

Therefore, the grapes must be placed in boxes weighing no more than 18-20 kg to prevent them from being compressed and losing juice.

Grape harvesting takes place around the second half of August to ensure good levels of acidity in the grapes and a potential alcohol content of 9.5°.

PRESSING

The grapes are pressed in three stages.

Pressing of the grapes is carried out with pneumatic presses that utilize the uniform pressure of air generated by a compressor against the walls of the perforated cage. From 100 kg of grapes, 65 liters of wine can be obtained.

Another machine that can be used for pressing is the Marmonier Vertical Press: this wooden press has a container width of 3 meters in diameter and a limited height of only 120 cm, to reduce the flow time of the must and allow very gentle squeezing of only mature grapes, without crushing the skins, , with a yield of 35%-40%. The gentle pressing of both machines allows the grape berry to retain all its organoleptic qualities. The result obtained is the “mosto fiore”, the highest quality of grape must.

In climatically favorable years, there is the possibility of increasing the wine yield by an additional 13hl; this is the reserve harvest and must be stored in mass for a minimum period of 12 months.

FIRST FERMENTATION

Our press and the entire area designated for pressing are located above the fermentation room, allowing us to take advantage of the natural flow of the must by gravity, without the use of pumps.

The must, along with selected yeasts, is then divided into stainless steel tanks or barrels depending on the type of grape, pressing method, and vineyard of origin.

The first fermentation of the classic method sparkling wines is the alcoholic fermentation, which is the natural transformation of the must into wine.

The must obtained from pressing is placed in temperature-controlled stainless steel tanks or wooden barrels, where selected yeasts and sugars are added to initiate the first fermentation.

The wine rests in the tanks and barrels until spring, resulting in a still wine with low alcohol content.

After several months, the wines from different tanks are tasted and blended to create the cuvée, which is the combination of several base wines.

If the base wines are from the same vintage for at least 85%, a Vintage (Millesimato) can be produced.

TIRAGE

Tirage, in technical terms, refers to the bottling operation. Once the cuvée is assembled, the wine is essentially transferred into bottles and added with liqueur de tirage, a solution composed of cane sugar and selected yeasts.

These yeasts will undergo the second, slow refermentation in the bottle. The quantity of sugar dissolved in the tirage syrup is 24 grams per liter for all types of Franciacorta, except for Satèn, where it is reduced to 20 grams per liter. 4g/l of sugar release an amount of CO2 corresponding to about 1 bar, these sugar quantities are necessary to develop a pressure of 6 atmospheres inside the bottle (5 for Satèn).

The bottles are then capped with a plastic capsule and a crown cap.

SECOND FERMENTATION

Once capped, the bottles are manually stacked and laid horizontally in the cellar at a temperature ranging from 13 to 16°C for the second fermentation, during which the yeasts feed on the sugars and transform them into alcohol and carbon dioxide (foaming).

The CO2 produced remains in the bottle, thus forming the typical perlage of the finished product.

From here, the yeasts that have undergone the second fermentation in the bottle undergo autolysis and settle on the side of the bottle, imparting to Franciacorta its distinctive aromas.

Aging on the lees has a minimum duration of 18 months for base wines, 24 months for Satèn and Rosé, 30 months for Millesimati, and 60 months for reserves.

REMUAGE

Once the aging period is complete, the bottles are placed on racks called pupitres, rotated daily on their axis by a few degrees, and gradually tilted with the neck downwards to gently allow the sediments to flow towards the cork and proceed to their expulsion.

DISGORGEMENT

The bottles, which are in a vertical position with the neck downward, are placed into a solution which causes a small block of ice to form inside the bottle’s neck, completely trapping the yeast sediment settled at the bottom due to gravity.

Once the neck is iced, the crown cap is removed, and the small ice block that has formed is expelled (with minimal wine loss) due to internal pressure.

The wine is then topped up with dosage syrup, a mixture of Franciacorta base wines and sugar in quantities that determine the type of Franciacorta:

Pas dosé or Dosage zero: < 3 g/l

Extra brut: ≤ 6 g/l

Brut: < 12 g/l

Extra dry: 12-17 g/l

Dry or Sec: 17-32 g/l

Demi sec: 33-50 g/l

DRESSING

Finally, the bottles are sealed with the cork stopper secured by the wire cage and vigorously shaken to mix the dosage syrup thoroughly. Kept for several more months in the cellar to allow the wine to settle, the bottles are then packaged with the label, capsule, DOCG seal, back label, and placed in the packs.

TASTING

The tasting phase of the wines is the culmination of the journey.

It’s the subjective and individual exploration of the wine and its nuances.